Point1

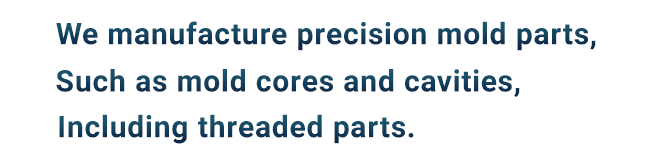

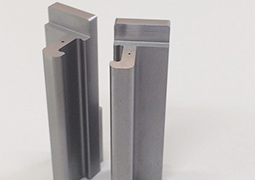

Mold core and cavity manufacturing

We can apply our technical capabilities to manufacture precision parts with micron-order machining.

Point2

Threading

We excel at threading high-precision special screws.

Point3

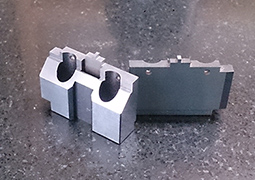

Cemented carbide machining

We accept orders for machining cemented carbide into round and square shapes.

Point4

Precision machining

We manufacture high-precision products by making the most of various machinery and equipment for machining, including profile grinding

Point5

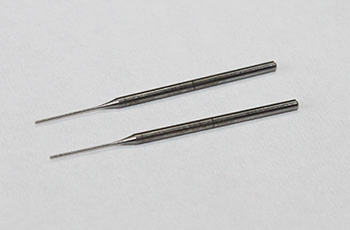

Inspection system

We make the most of inspection equipment to responsibly inspect the products we manufacture.

Mold nests

Round parts

Punches

Cemented carbide parts

Threaded parts(double-start thread)

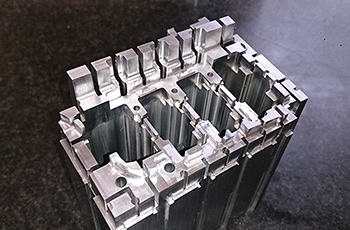

Connector core pins

Core pins

Machined parts

| Equipment | Manufacturer | Model | Quantity |

|---|---|---|---|

| NC lathes | Tsugami | M06SY | 1 |

| Tsugami | NT25 | 1 | |

| NC cylindrical grinder | Tsugami | G18-II | 1 |

| NC profile grinders | Amada Washino |

GLS-150GL GLS-130AS |

2 |

| Forming and grinding machines | Amada and Nikko | TFH1,NFG-515 Series | 5 total |

| Cylindrical grinder | Sakaino | MT-450 | 1 |

| Special cylindrical grinders | Washino | DEDTRUE | 3 |

| Centerless grinders | Nippon Seiki | MG-16H | 2 |

| Die-sinking EDM machine | Aitronix | AX1601 | 1 |

| Wire EDM machine | Mitsubishi Electric | FA20PS-Advance | 1 |

| General-purpose tool grinder | EWAG | WS-11 | 1 |

| ROBOMACHINE | FANUC | ROBODRIL a-D21MiB5 | 1 |

| Equipment | Manufacturer | Model | Quantity |

|---|---|---|---|

| Coordinate measuring machine | Carl Zeiss | O-INSPECT | 1 |

| Measuring microscopes | Nikon | MM-400/LT MM-800/L |

3 in total |

| Projectors | V-12B | 2 | |

| One-shot 3D shape measuring machine | Keyence | VR-5000 | 1 |

| Image size measuring instrument | IM-7000 | 1 | |

| Handheld probe coordinate measuring machine | XMC-1000 | 1 |

Takeishi Alloy Industry has offices in Shanghai, China and in Ho Chi Minh City in Vietnam. We manufacture

parts in collaboration with local factories.

Technical capabilities in China and Vietnam have evolved remarkably, and they can now handle various kinds

of

processing.

Staff at the offices and Takeishi Alloy Industry responsibly give instructions to local factories.

We will work together as a unit with our partner factories to maintain low costs, quick turnarounds, and

high

quality.

| Name | TAKEISHI ALLOYTOOL VIETNAM CO,.LTD |

|---|---|

| Location | Workshop B2-1c, ready built factory area plot B Long Hau – Hiep Phuoc street, Long Hau IP Long Hau, Can giuoc, Long An Province |

| TEL | (+84)28 3620 7547 |

| Person in charge | Nguyen Quoc Toan |

| toan.uc@takeishi-at.com |

| Equipment | Quantity |

|---|---|

| Centerless grinder | 1 |

| Milling machine | 1 |

| Lathe | 1 |

| Griding machines | 1 |

| ROBOMACHINE | 1 |

| NC griders | 3 |

| NC lathes | 1 |

| Equipment | Quantity |

|---|---|

| Cylindrical grinders | 3 |

| Inner diameter grinder | 1 |

| Bench lathe | 2 |

| Image size measuring instrument | 1 |

| Wire EDM machine | 1 |

| Die-shinking EDM machine | 1 |

| Name | TAKEISHI ALLOYTOOL CO,.LTD |

|---|---|

| Representative Director | Sumio Takeuchi |

| Location | 4-1-12 Higashisuna, Koto-ku, Tokyo 136-0074 |

| TEL | 03-3644-7298 |

| FAX | 03-3644-2391 |

| Business | ・Manufacturing and sales of all kinds of mold parts for plastic molding, press molding, and cold

forging ・Manufacturing and sales of all kinds of machine parts ・Manufacturing and sales of jigs and tools, threaded parts, and cemented carbide parts |

| Capital | 5 million yen |